Standards

ISO 22000 - food safety management system

We prepare your company for ISO 22000 certification: set up HACCP, prerequisite programs, traceability, incident response, and evidence-based process control.

What companies benefit most from ISO 22000 certification preparation

The standard brings the highest value to food chain companies that need to manage safety systematically and pass audits consistently.

Food manufacturers

When processes have many stages, ISO 22000 structures hazard control and helps stabilize safe product output in daily operations.

Ingredient producers

For ingredient manufacturers, the standard sets transparent requirements for HACCP, prerequisite programs, and batch traceability for stable daily execution.

Food logistics

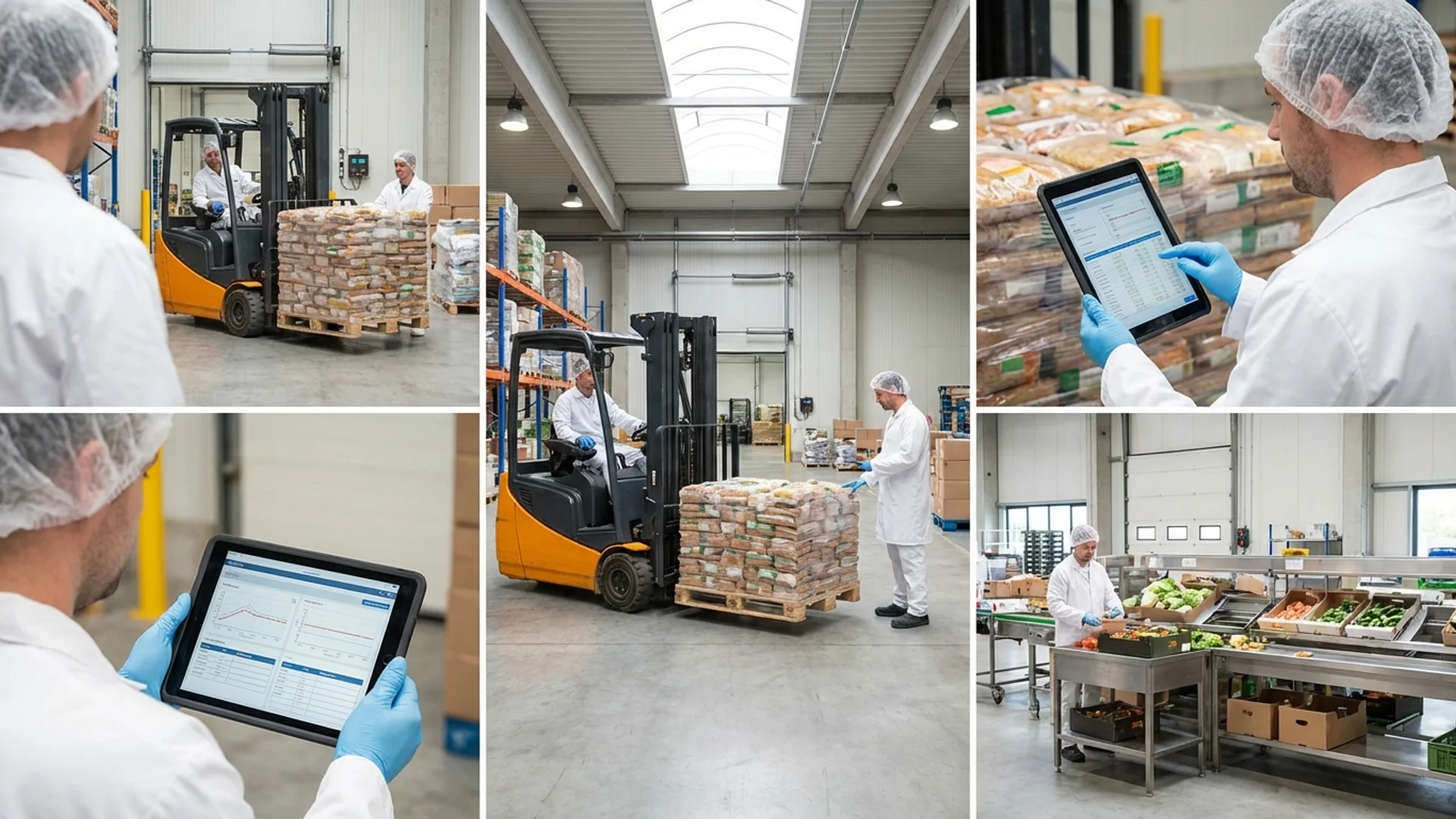

ISO 22000 helps control risks in transportation, storage, and shipment, reducing incident risk across the supply chain in daily operations.

Export companies

The system proves food safety control, record discipline, and team accountability for international buyers and partners in daily operations.

ISO 22000 implementation for food enterprises

ISO 22000 is especially useful for food chain companies that need to reduce risks and increase customer trust.

Food product manufacturers

Ingredient and additive producers

Logistics and warehouse operators

ISO 22000 requirements in plain language

HACCP, prerequisite programs, traceability, and corrective actions create an evidence-based system for ISO 22000 certification preparation.

HACCP and hazard control

Current hazard analysis and critical controls reduce incident risk and increase process reliability.

Prerequisite programs

Sanitation, hygiene, environmental control, and personnel control create a stable foundation for safe production.

Traceability and incidents

Fast batch traceability and clear incident response reduce losses and protect reputation.

Corrective actions

Systematic CAPA removes root causes of nonconformities and prevents recurrence of critical issues.

ISO 22000 audit: what is included in preparation

A practical food safety system implementation plan: from scope and HACCP to internal audits and certification readiness.

Need an individual implementation plan?

FSMS scope and objectives

We define ISO 22000 scope: products, processes, sites, roles, and key customer requirements.

HACCP and risks

We update hazard analysis, validate control measures, and define risk management priorities.

Prerequisite programs

We set up PRPs, assign owners, and define control criteria for stable safety in operational processes.

Documentation without bureaucracy

We prepare a minimally sufficient set of procedures and records that teams actually use in daily work.

Internal audit

We run internal checks, record gaps, and launch corrective actions with effectiveness control.

Audit readiness

We build the evidence package for ISO 22000 certification audit and prepare the team for inspection.

Need an individual implementation plan?

ISO 22000 implementation services: why companies choose Ekontrol

We turn standard requirements into controlled outcomes: fewer incidents, stable food safety, and predictable audit readiness.

Without systematic support

- Hazard control is inconsistent. Critical risks remain without sufficient attention and keep recurring in production.

- Traceability and records are fragmented. During inspections, the team loses time searching for evidence and confirmations.

- Audit preparation turns into last-minute rush. Work is done at the final moment, and systemic gaps stay unresolved.

With us toward results

- Diagnostics and clear priorities. We show which gaps are critical for food safety and what to fix first.

- Working processes and control. We configure the system so ISO 22000 works in daily operations.

- Support through certification. We prepare the team, run a pre-audit, and support the final audit stage.

ISO 22000 implementation stages from diagnostics to audit

We work in short stages focused on safety and audit readiness without last-minute rush.

Fast start with diagnostics

Within 3-5 days we identify gaps, risks, and priorities to launch implementation immediately.

Implementation in working processes

We configure HACCP, PRPs, records, and training for the enterprise's real operational activity.

Pre-audit and certification support

We prepare the evidence base, train staff, and support the audit until confident completion.

Request ISO 22000 certification preparation

We will run diagnostics, create a roadmap, and support your team to confidently pass certification audit.

Get implementation plan