Industries

Defense Industry - Process Control and Evidence Readiness for the Customer

Ekontrol web services help manufacturers meet customer requirements: change control, traceability, supplier workflows, and records for audits.

What the customer and auditor expect

The focus is on process control, change control, and evidence-backed quality of deliveries.

Product and configuration control

Version and change control in technical documentation, defined ownership, and complete change history for each batch, with no gap between requirements and reality.

Evidence-backed delivery quality

Acceptance criteria, incoming inspection, supplier assessment, and test and inspection records that auditors expect to see on the first request.

Is your customer audit already scheduled?

We will assess readiness and prepare your evidence base with minimal risk.

Assess readinessQuality process control and customer audit requirements

Three key outcomes customers expect: change control, batch traceability, and an evidence package for inspections.

Change and configuration control

Single versioning and ownership rules ensure documentation matches actual production and changes are controlled across all departments.

Component traceability

The path of materials and batches from incoming inspection to finished product is reproducible, record-backed, and quickly available for auditor review.

Evidence package for audit

Incoming inspection records, test protocols, and corrective actions are assembled into a clear evidence package ready for submission.

Customer audit: key manufacturer requirements

A concise view of what customers actually check: change control, batch traceability, evidence package quality, and process stability.

Change and version control

Documentation, drawings, and instructions are current and traceable in all working versions without discrepancies, with key production changes and owners clearly recorded.

Material and batch traceability

A clear component path from incoming inspection to finished product, confirmed by system records and logs without data loss or gaps.

Incoming inspection and suppliers

Acceptance criteria, risk assessment, and response to supply deviations and related incidents, with aligned team actions and ownership.

Nonconformities and corrective actions

Root causes are defined, actions are completed, and effectiveness is verified against real process outcomes, with on-time closure and evidence.

Control records and stability

There is proof that the process works consistently, not only once for or right before an audit, with regular records and trend analysis.

Need a readiness review before audit?

Get consultationPreparing a manufacturer for customer audit

A structured approach: from requirement and risk assessment to a complete evidence package and a prepared team.

Requirements and risk diagnostics

We collect customer requirements, document the inspection format, identify critical points and risks, and build a gap and priority list for controlled preparation.

Process map and change control

We describe processes, owners, and control points, and align document change rules. We implement version control without discrepancies between documents and reality.

Evidence quality in production

We set up logs, protocols, and confirmations for control of key operations and verify batch traceability. We structure evidence for fast auditor review.

Internal audit

We run an internal check, rehearse auditor questions, and prepare the team to demonstrate processes. We close weak points before the audit.

Preparation result

A set of evidence and rules that makes audits predictable.

- Customer requirement register

- Traceability matrix

- Corrective action plan

- Audit record package

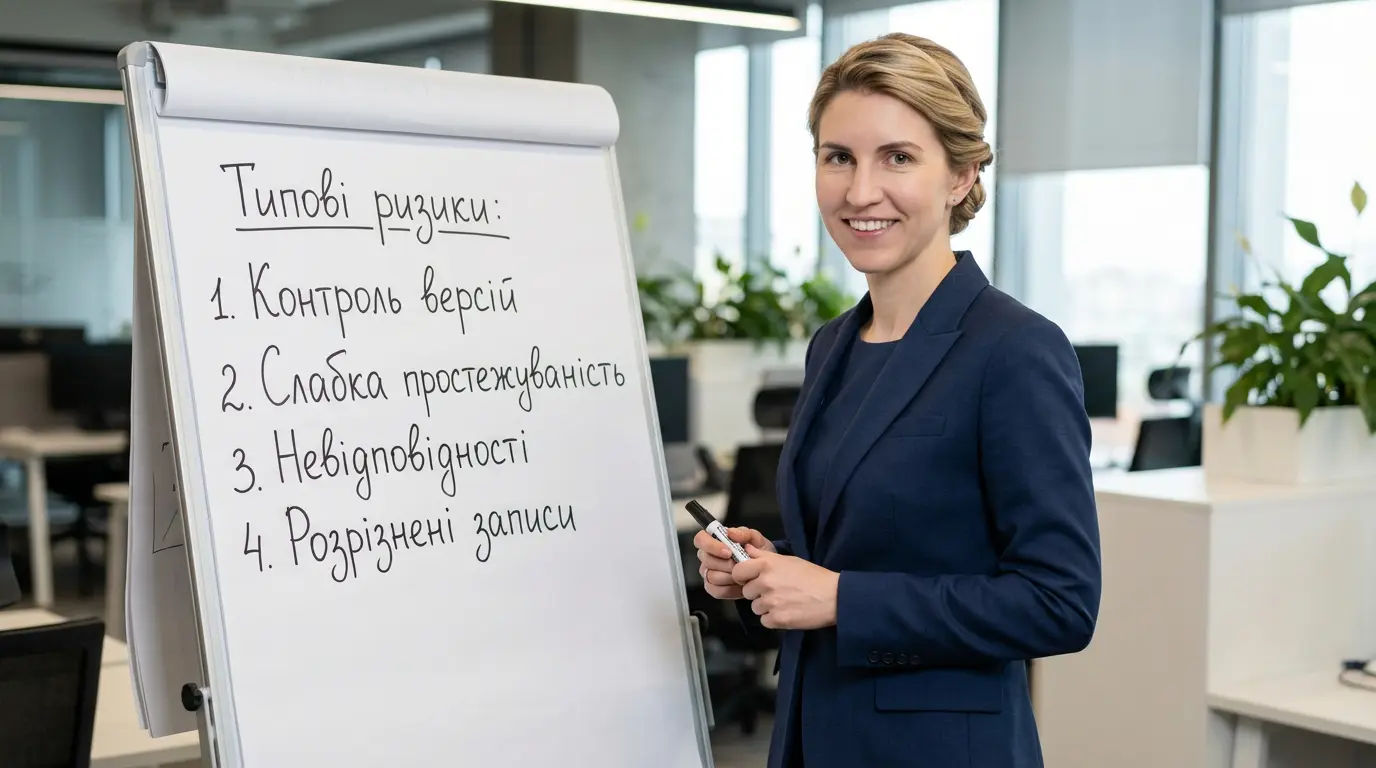

Typical risks that break audits

The most common manufacturer mistakes that lead auditors to raise critical findings. We help prevent them in advance.

Changes without version control

Documentation is updated, but production follows different instructions. The auditor sees a gap between documents and actual practice.

Weak batch traceability

There is no real-batch check of the chain from input to output. This is one of the auditor's first tests.

Nonconformities without root-cause work

Deviations are recorded, but root causes are not removed. As a result, problems repeat.

Fragmented records

Evidence is stored in different formats and locations, making it hard to show quickly to the auditor.

Let's discuss services for defense manufacturing

We will propose a support plan tailored to your requirements: change control, component traceability, supplier management, and customer audit preparation.

Contact us